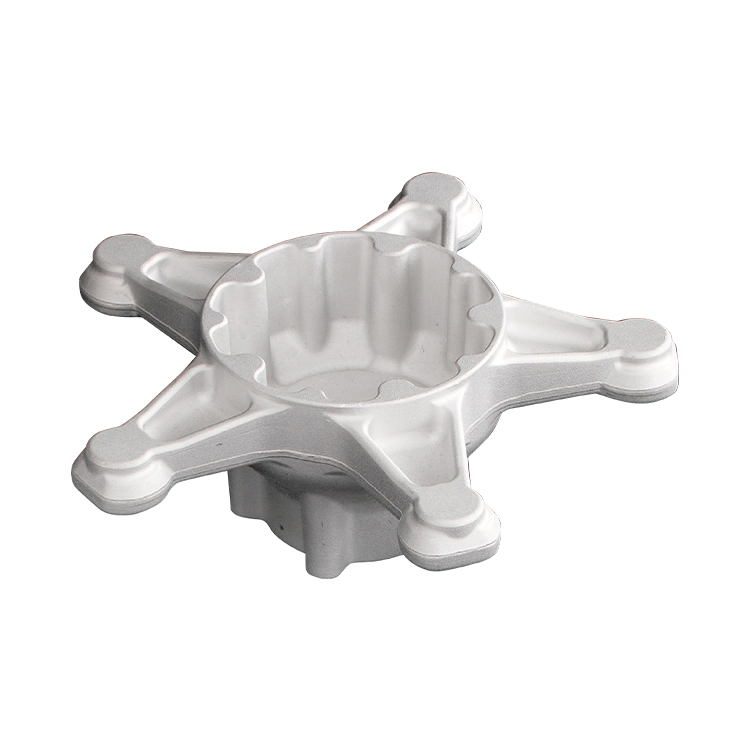

Hub

An aluminum forging automobile hub is a component of a vehicle's wheel assembly that is made by forging aluminum. Forging is a manufacturing process that involves shaping metal by pressing, pounding, or squeezing it while it is in a heated and malleable state. This process can create parts that are stronger and more durable than those made using other manufacturing methods.

An aluminum forging automobile hub is typically used in the production of high-performance vehicles, as it is lightweight and has a high strength-to-weight ratio. It can also be used in the production of other types of vehicles, such as passenger cars and trucks, to help reduce weight and improve fuel efficiency.

It's important to do your own research and evaluate the quality and performance of any aluminum forging automobile hub you're considering using. Factors such as the design and manufacturing processes used, as well as the material properties of the aluminum, can all impact the performance of the hub.

Forging aluminum automobile hubs is a complex process that typically involves the following steps:

Design and development - The first step in making an aluminum forging automobile hub is to design and develop the part. This involves creating a computer-aided design (CAD) model of the hub, which is used to create a prototype and ensure that the design meets the necessary performance and strength requirements.

Die design and production - The next step is to design and produce the dies that will be used to shape the aluminum into the desired shape. Dies are specialized tools that are used to forge or stamp metal into the desired shape.

Aluminum melting and casting - The aluminum alloy that will be used to make the hubs is melted in a furnace and poured into a mold to create a rough casting.

Heat treatment - The rough casting is then heat treated to strengthen the metal and improve its properties.

Forging - The heat-treated casting is then placed in a forging press, where it is shaped into the final shape of the hub using high pressure and temperature.

Machining - The forged hub is then machined to remove any excess material and create the final shape and features of the part.

Surface finishing - The hub is then subjected to various surface finishing processes, such as sandblasting or polishing, to give it a smooth, attractive finish.

Quality control and inspection - Finally, the finished hub is inspected to ensure that it meets the required specifications and standards.

It is important to note that forging aluminum automobile hubs is a highly specialized process that requires specialized equipment, skilled labor, and a high level of expertise.